Stakpure Technical background

Reverse osmosis removes up to 99 % of all water pollution, such as minerals, bacteria and any further particles. The typical WCF rate (utilization rate) of reverse osmosis systems stands at 70/30 or rather optimally at 75/25. Adaptation of concentrate treatment can increase the yield up to 85 %.

Principle and mode of operation

Osmosis is based on a natural process such as plants use their root cells to gain moisture from soil. The same process takes place in human body and causes exchange of substances within the cell membrane.

If you separate two differently loaded liquids by a cell membrane, liquid molecules will move towards the less concentrated solution according to the principle of Brownian motion. This leads to osmotic pressure. In order to gain as pure water as possible, considerably higher pressure is generated on the loaded side. Hence the process is reversed and therefore it is called reverse osmosis.

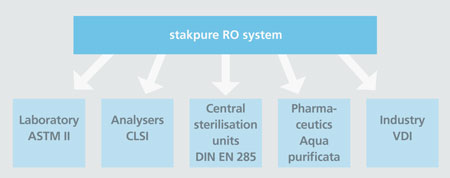

Reverse osmosis systems are ideal for supplying pure water to entire building wings in laboratory (Type III), cleaning and disinfection units in medical technology (DIN EN ISO 15883) as well as industrial applications.

Benefits at a glance

• One central system – space-saving

• No regeneration costs

• No use of chemicals

• Free from particles and bacteria

• High pure water yield

• Modular capacity upgrade

Electro-deionization

Electro-deionisation combines two processes for producing ultrapure water, the electrodialysis and ion exchanger processes (IEP).

Whereas the conventional ion-exchanger process involves chemically regenerating the resins on a regular basis after longer time use, electro-deionisation continuously regenerates the resins using electric current.

Principle and mode of operation

With electro-deionisation, water is split into H+ and OH- ions by applying an electric voltage within the cells. This creates a process that continuously regenerates the mixedbed resins without adding chemicals. Ions are held back on the mixed-bed resins and flushed out through selective membranes that only let anions or cations through. This process rules out any occurrence of impurities and the risk of „impure mixed-bed resins“ contaminating the pure water that is produced. Electro-deionization systems produce a constantly high water quality, making them ideal for supplying pure water to entire building wings in the laboratory (Type II), central sterilisation units in clinics (DIN EN 285) as well as for many pharmaceutical and industrial applications.

Reverse osmosis removes up to 99 % of all water pollution, such as minerals, bacteria and any further particles. The typical WCF rate (utilization rate) of reverse osmosis systems stands at 70/30 or rather optimally at 75/25. Adaptation of concentrate treatment can increase the yield up to 85 %.

Principle and mode of operation

Osmosis is based on a natural process such as plants use their root cells to gain moisture from soil. The same process takes place in human body and causes exchange of substances within the cell membrane.

If you separate two differently loaded liquids by a cell membrane, liquid molecules will move towards the less concentrated solution according to the principle of Brownian motion. This leads to osmotic pressure. In order to gain as pure water as possible, considerably higher pressure is generated on the loaded side. Hence the process is reversed and therefore it is called reverse osmosis.

Reverse osmosis systems are ideal for supplying pure water to entire building wings in laboratory (Type III), cleaning and disinfection units in medical technology (DIN EN ISO 15883) as well as industrial applications.

Benefits at a glance

• One central system – space-saving

• No regeneration costs

• No use of chemicals

• Free from particles and bacteria

• High pure water yield

• Modular capacity upgrade

Electro-deionization

Electro-deionisation combines two processes for producing ultrapure water, the electrodialysis and ion exchanger processes (IEP).

Whereas the conventional ion-exchanger process involves chemically regenerating the resins on a regular basis after longer time use, electro-deionisation continuously regenerates the resins using electric current.

Principle and mode of operation

With electro-deionisation, water is split into H+ and OH- ions by applying an electric voltage within the cells. This creates a process that continuously regenerates the mixedbed resins without adding chemicals. Ions are held back on the mixed-bed resins and flushed out through selective membranes that only let anions or cations through. This process rules out any occurrence of impurities and the risk of „impure mixed-bed resins“ contaminating the pure water that is produced. Electro-deionization systems produce a constantly high water quality, making them ideal for supplying pure water to entire building wings in the laboratory (Type II), central sterilisation units in clinics (DIN EN 285) as well as for many pharmaceutical and industrial applications.