Nabertherm LT 15/12/C550 muffle furnace

• Heating from two sides by ceramic heating plates (heating from three sides for muffle furnaces L 24/11 - LT 60/12) for an optimal temperature uniformity

• Temperature uniformity of +/− 5 K with closed fresh-air inlet in empty work space according to DIN 17052-1 at working temperatures above 800 °C

• Thermocouple type S (1200 °C)

• Ceramic heating plates with integral heating element which is safeguarded and easy to replace

• With lift door (LT)

• Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

• Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

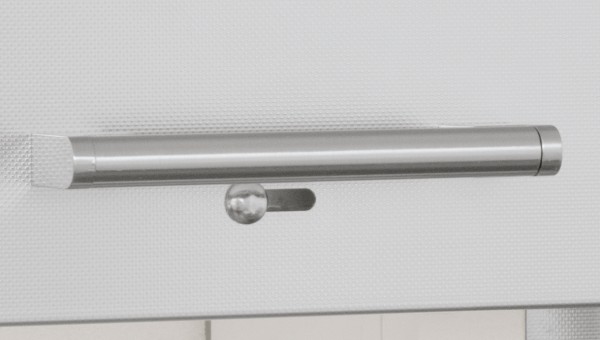

• Adjustable air inlet integrated in door (see illustration)

• Exhaust air outlet in rear wall of furnace

• Controller with touch operation C550

• Solid state relays provide for lownoise operation

The muffle furnaces L 3/11 - LT 60/12 have been proven for daily laboratory use. These models stand out for their excellent workmanship, advanced and attractive design, and high level of reliability.

Standard Equipment

• Heating from two sides by ceramic heating plates (heating from three sides for muffle furnaces L 24/11 - LT 60/12) for an optimal temperature uniformity

• Temperature uniformity of +/− 5 K with closed fresh-air inlet in empty work space according to DIN 17052-1 at working temperatures above 800 °C

• Thermocouple type S (1200 °C)

• Ceramic heating plates with integral heating element which is safeguarded and easy to replace

• With lift door (LT)

• Dual shell ventilated housing made of textured stainless steel sheets for low surface temperature and high stability

• Exclusive use of insulation materials without categorization according to EC Regulation No 1272/2008 (CLP). This explicitly means that alumino silicate wool, also known as “refractory ceramic fiber” (RCF), which is classified and possibly carcinogenic, is not used.

• Adjustable air inlet integrated in door (see illustration)

• Exhaust air outlet in rear wall of furnace

• Controller with touch operation C550

• Solid state relays provide for lownoise operation

Option

• Chimney, chimney with fan or catalytic converter (not for L 1 and L 15)

• Over-temperature limiter with adjustable cutout temperature as temperature limiter to protect the furnace and load

• Protective gas connection to purge with non-flammable process gases (not available in combination with chimney, chimney with fan or catalytic converter) not gas tight

• Manual or automatic gas supply system

• Port for thermocouple in the rear wall or in the furnace door

Specifications for Nabertherm LT 15/12/C550 muffle furnace

| Interior volume (liter) | 15 |

| Net weight (kg) | 43 |

| Temperature maxium | 1200˚C |

| Internal dimension (WxHxD) (mm) | 230x340x170 |

| Connected load in kW | 3.5 |

| Electrical conneciton | 1 ph |

| Heating time in min | 99 |

| Controller | C 550 |